Steel cord conveyor belt are widely used in coal, mine, port, metallurgy, power, chemical industries and suitable for high strength,long distance and heavy load transportation of materials.

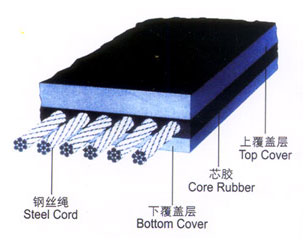

Characteristics of steel cord conveyor belt

We use new-type structure of steel cord as tension element, which has the following advantages, such as high tensile strength, low elongation, good troughability and bending resistance.

Core rubber can permeates the narrow space among strands of steel cord. The adhesive strength between rubber and steel cord is big and makes the belt a good rust protection. Weaken the shear and torsion force among strands. dynamic fatigue, which make the belt a longer working life.

Anti-tear (transverse reinforcement) Steel Cord Conveyor Belt

Structure

We use new structure steel cord as tension element. We use steel cord & thread, fiber rope, fabric as the reinforcement which is placed vertical to longitudinal steel cord.

Characteristics

Good impact and tear resistance.

Tear resistant conveyor belt with detector

Structure

We uses new-structure steel cord as the tension element. Between belt core rubber and bottom cover, we build in phase-shift sensor (loops) along longitudinal direction at regular distances.

Structure diagram

Characteristics

By microcomputer programming control, it will immediately give an alarm and automatically stop running the moment that belt tearing signs are detected.

It will immediately give an alarm and automatically stop running the moment that the belt running speed reduces abnormally.

It has memory function that displays running data and status of belt.

Main technical data

Of fire resistant steel cord conveyor belt for coal mine produced as per MT668-2008 standard

|

Item |

Belt tensile strength |

|||||||||||||

| ST/S 630 |

ST/S 800 |

ST/S 1000 |

ST/S 1250 |

ST/S 1600 |

ST/S 2000 |

ST/S 2500 |

ST/S 2800 |

ST/S 3150 |

ST/S 3500 |

ST/S 4000 |

ST/S 4500 |

ST/S 5000 |

ST/S 5400 |

|

|

Longitudinal tensile strength |

630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 2800 | 3150 | 3500 | 4000 | 4500 | 5000 | 5400 |

|

Max. nominal diameter of steel cord |

3.0 | 3.5 | 4.0 | 4.5 | 5.0 | 6.0 | 7.2 | 7.5 | 8.1 | 8.6 | 8.9 | 9.7 | 10.9 | 11.3 |

|

Steel cord pitch |

10±1.5 | 10±1.5 | 12±1.5 | 12±1.5 | 12±1.5 | 12±1.5 | 15±1.5 | 15±1.5 | 15±1.5 | 15±1.5 | 15±1.5 | 16±1.5 | 16±1.5 | 17±1.5 |

|

Top cover thickness |

5 | 5 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8.5 | 9 |

|

Bottom cover thickness |

5 | 5 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8.5 | 9 |

|

Width |

Number of steel cord |

|||||||||||||

| 800 | 75 | 75 | 63 | 63 | 63 | 63 | 50 | 50 | 50 | 50 | ||||

| 1000 | 95 | 95 | 79 | 79 | 79 | 79 | 64 | 64 | 64 | 64 | 64 | 59 | 55 | 55 |

| 1200 | 113 | 113 | 94 | 94 | 94 | 94 | 76 | 76 | 76 | 77 | 77 | 71 | 66 | 66 |

| 1400 | 133 | 133 | 111 | 111 | 111 | 111 | 89 | 89 | 89 | 90 | 90 | 84 | 78 | 78 |

| 1600 | 151 | 151 | 126 | 126 | 126 | 126 | 101 | 101 | 101 | 104 | 104 | 96 | 90 | 90 |

| 1800 | 171 | 171 | 143 | 143 | 143 | 143 | 114 | 114 | 114 | 117 | 117 | 109 | 102 | 102 |

| 2000 | 196 | 196 | 159 | 159 | 159 | 159 | 128 | 128 | 128 | 130 | 130 | 121 | 113 | 113 |

| 2200 | 216 | 216 | 176 | 176 | 176 | 176 | 141 | 141 | 141 | 144 | 144 | 134 | 125 | 125 |

Types and standards of steel cord conveyor belt

Types

According to cover rubber properties, it can be divided into the following types: general type, fire resistant type for coal mine, fire resistant type for general purpose, cold resistant type, abrasion resistant type, acid-alkali resistant type, oil resistant type, etc.

Standards

|

Types |

Applicable standards |

|

General |

GB/T9770-2013 |

|

Fire resistant for coal mine |

MT668-2008 |

|

Fire resistant for general purpose |

HG/T3973-2008 |

|

Heat resistant |

GB/T20021-2005 |

|

Abrasion resistant |

Abrasion loss≤90mm3 |

|

Heat & abrasion resistant |

Below 125℃, abrasion loss≤150mm3 |

|

Tear resistant |

HG/T3646-1999 |

|

Cold resistant |

HG/T3647-1999 |